Our team at All Pipe Solutions has extensive experience in establishing plant quality assurance programs, from day-to-day operations to achieving ASTM F667, CSA B182.6/B182.8, and B&Q certifications.

We can provide a full range of testing equipment — from simple tests like parallel plate testing and carbon black analysis, to comprehensive CSA B182.6/B182.8 gasket testing for large diameter pipe manufacturers.

At All Pipe Solutions, our goal is to help our customers run an organized and efficient facility.

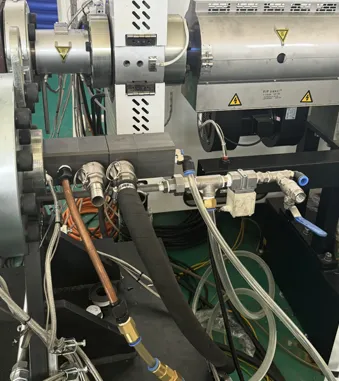

All your molds will be stored in clearly labeled crates, wiring will be properly secured, and all air, water, and vacuum lines will be clean, tidy, and out of the way. A well-organized plant isn’t just easier to work in—it’s safer and more productive.